Quality is an important factor when it comes to any product in our company. A business that provides quality builds trust, good reputation, and recognition by customers as well as regulatory bodies. With market competition getting higher and higher, quality has made a huge impact on customers’ choice of suppliers. Quality control is vital to building a successful business that delivers products that meet or exceed customers’ expectations. It also forms the basis of an efficient business that minimizes waste and operates at high levels of productivity. Obtaining ISO 16001 and IATF 16949:2016 quality control system is a strong foundation for making better products with higher recognition from our customers.

Internal and External Test

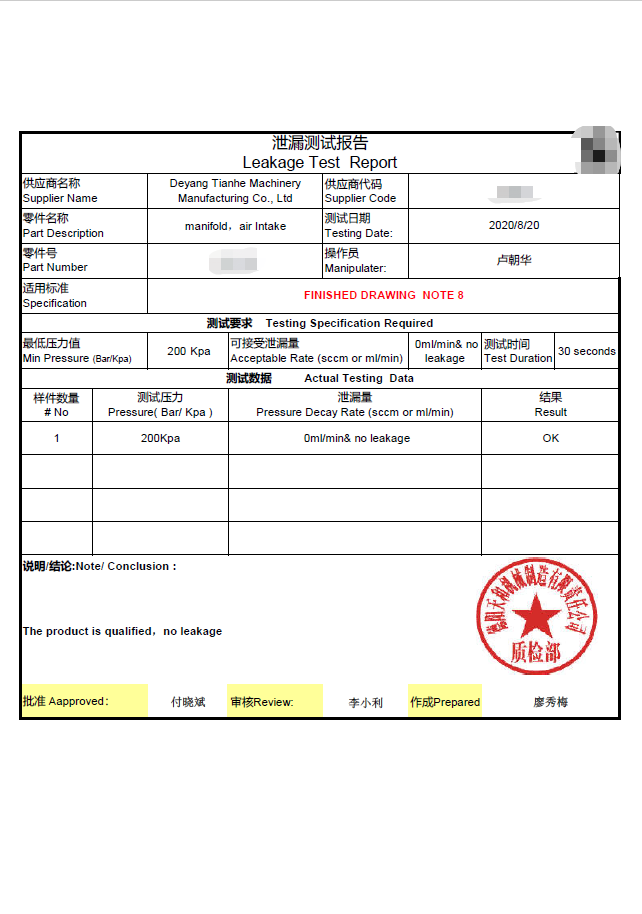

Internal quality control and external quality assurance is the key to maintaining customer satisfaction level and attracting potential clients. We have a series of internal testing equipment and random internal tests. In addition, we often have third parties do different external testing in accordance with customers’ requirements.

Test Equipment

Optical Emission Spectrometer

Usage: Analysis of all metals and alloys, especially in Aluminum and Aluminum alloy.

Aluminum Hydrogen Tester

Testing Scope: Aluminum density.

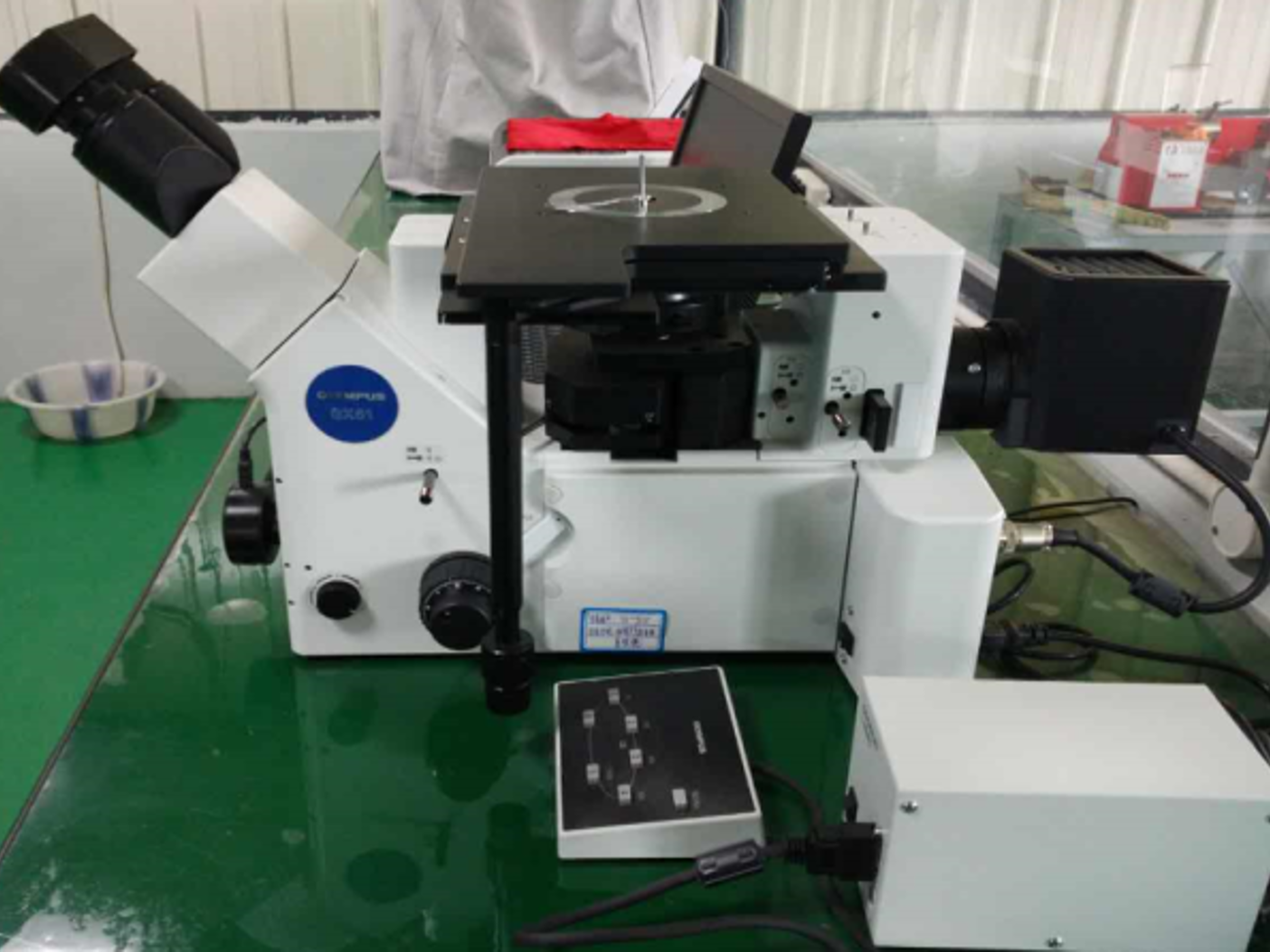

Inverted Microscope

Testing Scope: Iron and Aluminum Alloy.

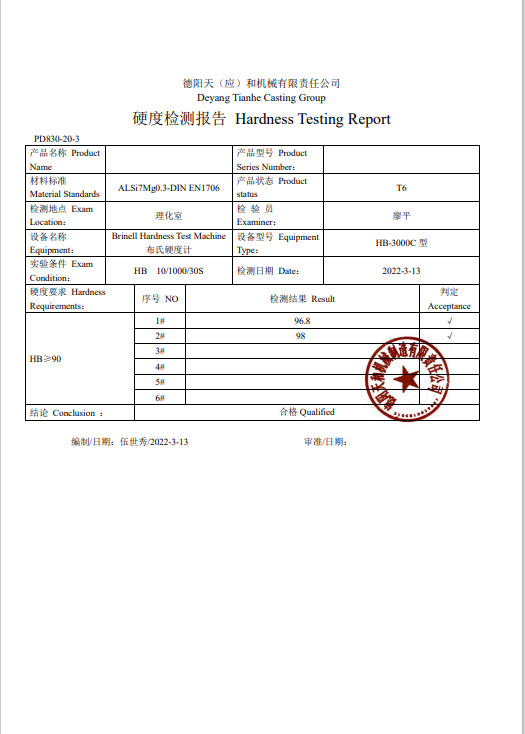

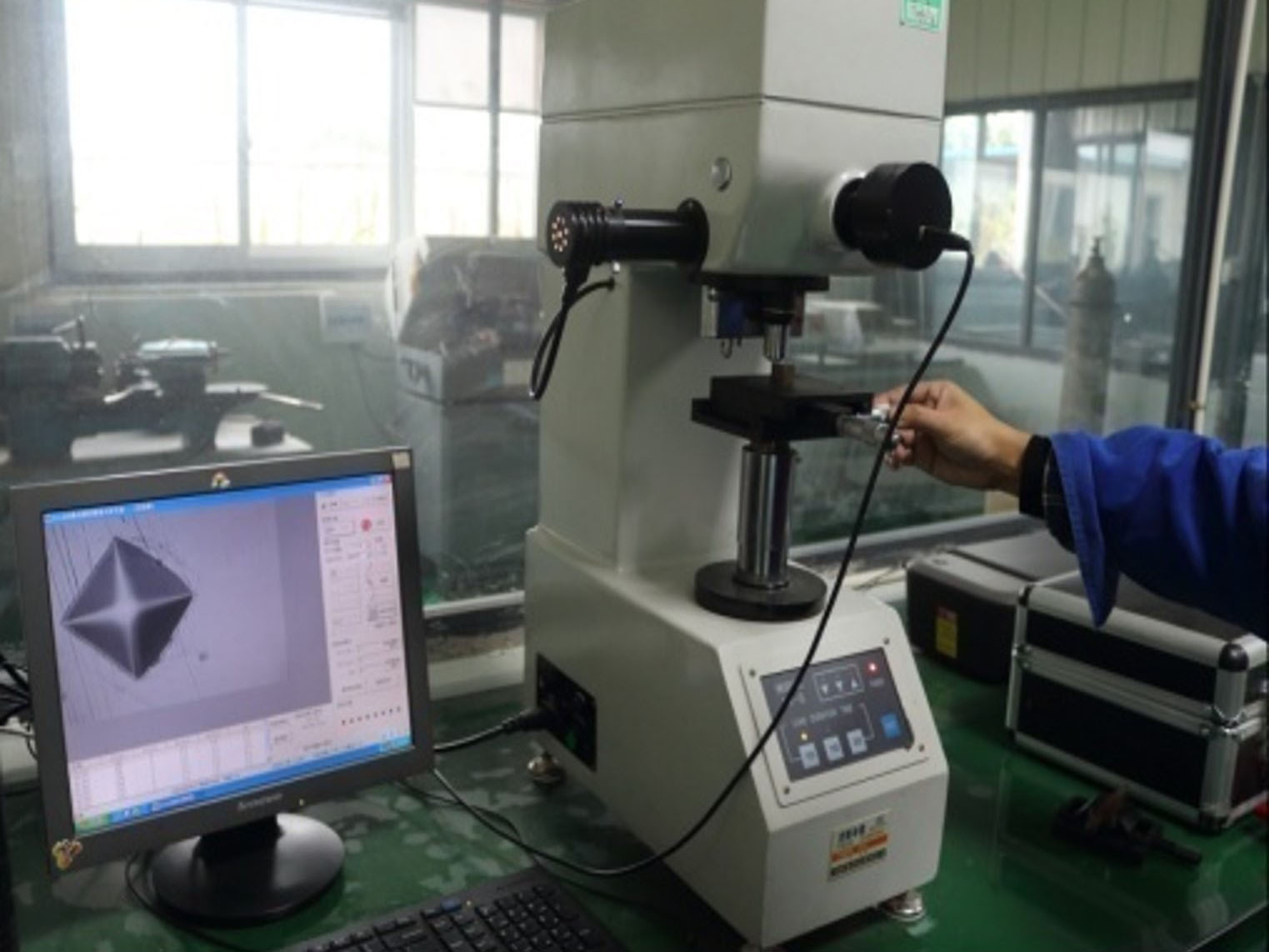

Hardness tester

Testing Scope: 8~450HBS/8~650HBW Hardness of Metallic Materials

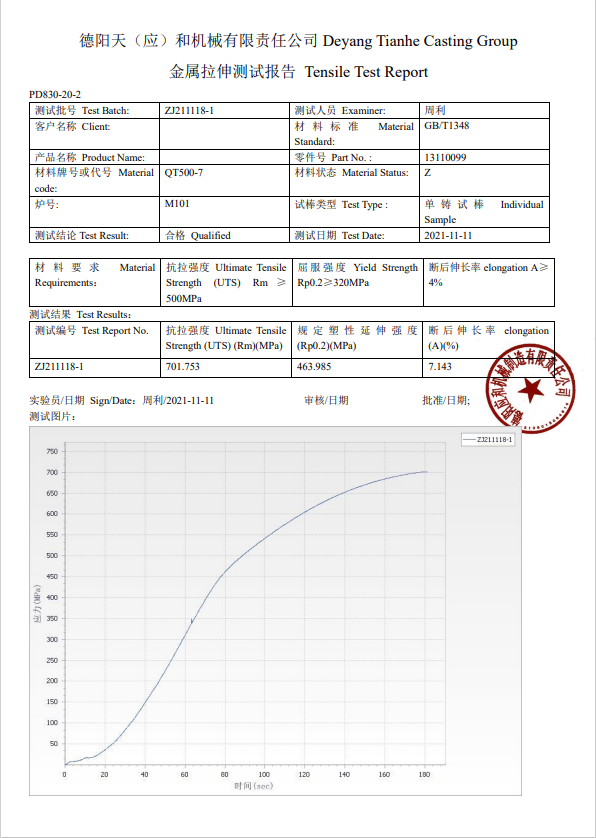

Material Cupping Machine

Testing Scope: Tensile Strength of metallic materials/Yield Strength/Elongation

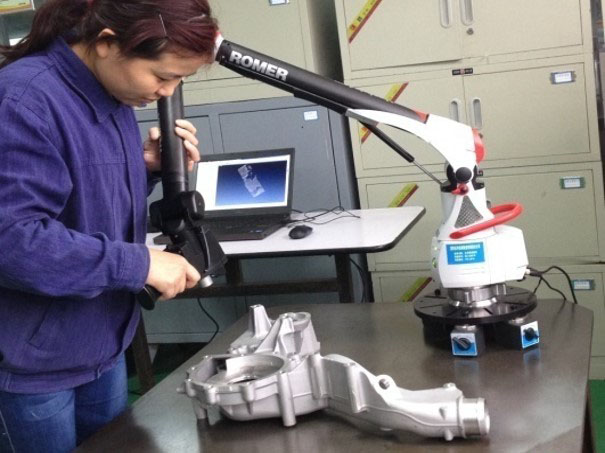

Articulated Coordinate Measuring Machine

Testing Scope: Product Size

Ultrasonic Thickness Meter

Testing Scope: Wall thickness of metal material.

Industrial endoscope

Testing Scope: carry out non-destructive inspections in the pipes or mechanical parts to ensure maintenance.

High X-ray image enhancer

Testing Scope: Defects flaws inside Aluminum Alloy.

Coordinate Measuring Machine

Precision:2.5+3.3L/1000μm

Testing Scope:700×1000×700

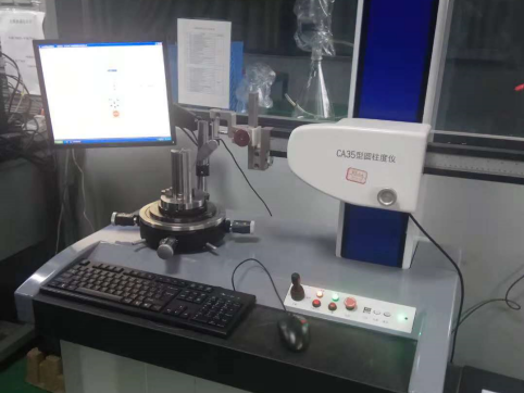

Roundness measuring instrument

Testing Scope: Cylindricity.

Pneumatic Measuring Instrument

Precision: ±1%

Testing Scope: 25μm